Bayer has led the implementation of an enhanced Integrated Pest Management system (“e-IPM”) based on 2 innovative molecules and the active release of specific beneficial insects. This approach is unique in Australian vegetables and provides growers the ability to produce vegetables in a way that enhances their environmental, economic and social sustainability. The novelty of this approach is to establish a simplified IPM (Integrated Pest Management) program using naturally occurring beneficial insects to attack target pests, and support these beneficials with new “soft” chemistry. A cross-industry consortium was created to develop, demonstrate and ensure product supply for the program.

Figure 1: Diadegma wasps target Diamondback moth larvae to protect brassica vegetables

Why We Did It

Horticultural producers are constantly battling with insects which adapt quickly to the control options. These insects are economically damaging, need constant vigilance and require new control measures continuously being developed. The major pest of flowerhead brassicas (cauliflower and broccoli) is diamondback moth (DBM) which due to prolific breeding, has rapidly built resistance to the currently available control options.

Resistance in Australian Agriculture is developing as a major threat to sustainable production. While IPM is a valuable management option, older broad spectrum products generally kill beneficial insect populations, making IPM difficult to implement. At the same time, the introduction of new crop protection products based on novel modes of action is declining due to increasing development cost and regulatory demands, further reducing IPM options. The overall result is an accelerated rate of resistance development.

In parallel, consumers are demanding greater knowledge about the source of their vegetables and the assurance that they are grown in the most sustainable manner, whilst all the time, insisting on blemish free produce.

Producers are therefore facing a significant production and marketing challenge.

Bayer has developed two new chemical pest control options (Belt® and Movento ® brand insecticides), with novel modes of action. A key feature of these product is that they target pests and leave most beneficial insects unharmed. Beneficial insects can thus be introduced early in the crop growth cycle, and they can continue to work in partnership with any chemical applications that are made later. These products have opened a unique opportunity to develop simplified IPM systems based on a true partnership between beneficial insects, low impact chemicals and management expertise.

Figure 2: Belt® is a new generation, selective insecticide from Bayer

What We Did

Phase 1: Research Phase.

Through contact with key integrated pest management researchers and a local beneficial insect breeding company, it became clear that the native beneficial parasitoid Diadegma semiclausum of diamond backed moth could form the basis of an environmentally sustainable flowerhead brassica production program for growers. The wasp can be artificially bred, and released into the crop prior to the arrival of the pest. A new, enhanced IPM (e-IPM) system was developed based on 4 key elements:

- The use of the beneficial insect Diadegma semiclausum.

- The use the biological pesticide based on Bacilus thuringensis (Bt).

- The targeted use of Belt ® and Movento® from Bayer.

- Management expertise provided by IPM consultants and farmers themselves.

Laboratory work was first conducted to investigate the intrinsic toxicity of Belt and Movento to the diadegma wasp. Fully replicated trials were conducted in Victoria and WA with local consultants, researchers and industry representatives to evaluate different methods of combining the beneficial insects , Belt® , Movento® and Bt. The systems were assessed for insect control efficacy, cost effectiveness and finally, the quality of produce, to ensure it met or exceeded supermarket specifications. New transport and release methodologies also had to be developed.

Figure 3: The e-IPM program Legend: Insect=Diadegma wasp, Flower=Bt insecticide, Molecule=Chemical Insecticide

Phase 2: Commercial release.

While Phase 1 confirmed the system’s technical success and strong interest from growers and retailers, broad scale commercial success was not yet assured. The 'e-IPM’ system required collaboration between groups that had not previously worked together. The beneficial insect industry had limited capacity and different commercial systems and traditional crop advisors were not trained in promoting IPM approaches. Bayer took the lead to coordinate meetings and achieved the strong support of several key players;

- Biological Services Pty Ltd as the provider of the diadegma wasp

- IPM Technologies Pty Ltd as the provider of high quality IPM services.

- EE Muirs and Sons as the distributor, coordinating orders and supply.

- AAA Farms (The Agosta Family) and Fresh Select as key ‘foundation’ growers.

Collaboration between these groups required establishing a new level of trust, but all the players were committed to deliver a more sustainable outcome for growers, retailers and their customers.

Figure 4: Field days and demonstrations were used to promote the system.

Phase 3: Promotion and Expansion.

Field days and demonstrations were conducted with attendees including growers, agronomists, industry researchers and major supermarkets. Based on strong interest the use of the system has spread from Werribee, Victoria to other parts of Victoria, WA and South Australia. In 2015, Horticulture Innovation Australia (HIA) launched a new program to promote IPM, to which Bayer is providing its input and expertise based on the e-IPM program.

Outcomes

The key outcome is to create a real world example of sustainable vegetable growing in large commercial, open field production systems. We believe it is an Australian and World first.

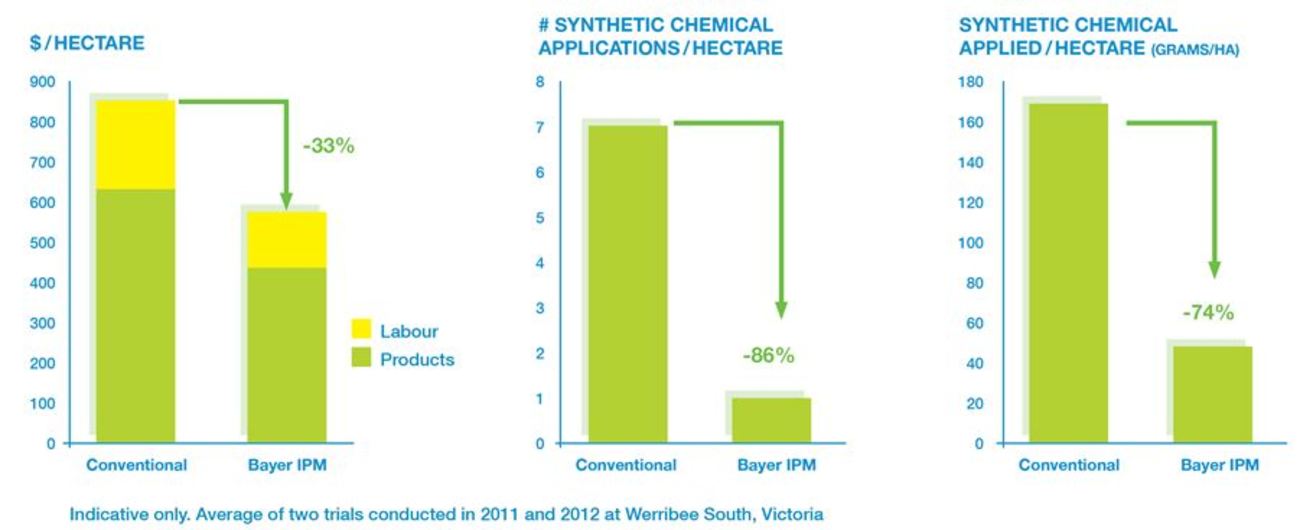

Figure 2: Indicative benefits from the e-IPM system

All three pillars of sustainability are addressed by the e-IPM approach.

- Environmental: The system leads to a direct reduction of up to 75% in the volume of synthetic pesticides used. In addition, the products used in the system are more targeted and selective than traditional products such as organophosphates and synthetic pyrethroids.

- Economic: The direct benefit to the grower include; Up to 33% reduction in insect control costs. Direct management of the resistance threat. Addressing the need of consumers by growing products in a more sustainable way. Such credible and sustainable practices underpin “clean green” claims and stronger commitments from retail customers have been reported.

- Society: At the farm level, workers report much less stress related to the lower number of pesticide applications, and use of more benign products. Growers can more clearly communication to their surrounding communities about the best practices they are using in their farms. Finally, grower stress is reduced, as the system has proved robust, with Belt® and Movento ® providing a safety net to IPM systems.

In 2012 Bayer received an Australian Marketing award, and in 2013, Bayer was included in BRW’s 50 most innovative companies based on the development of the system.

Acknowledgements:

Bayer

acknowledges the support and partnership of the follow companies and persons.

The

Agosta Family,

Fresh

Select Pty Ltd,

Biological

Services Pty Ltd,

EE

Muir and Sons,

Sumitomo

Chemicals

and

especially,

Dr Paul

Horne and Jessica Page of IPM Technologies Pty Ltd